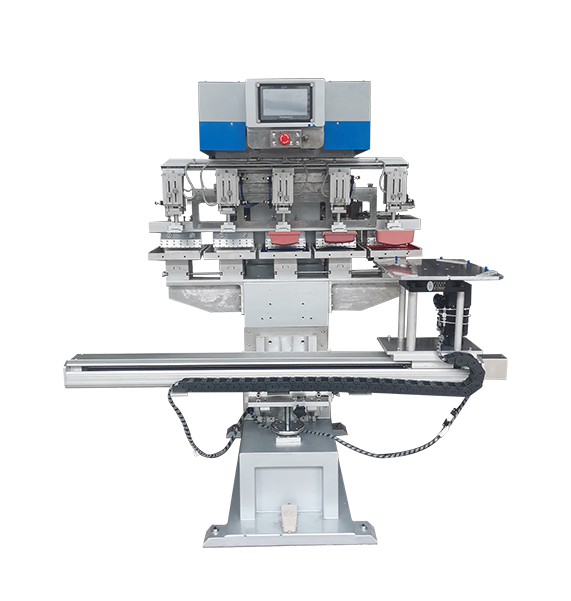

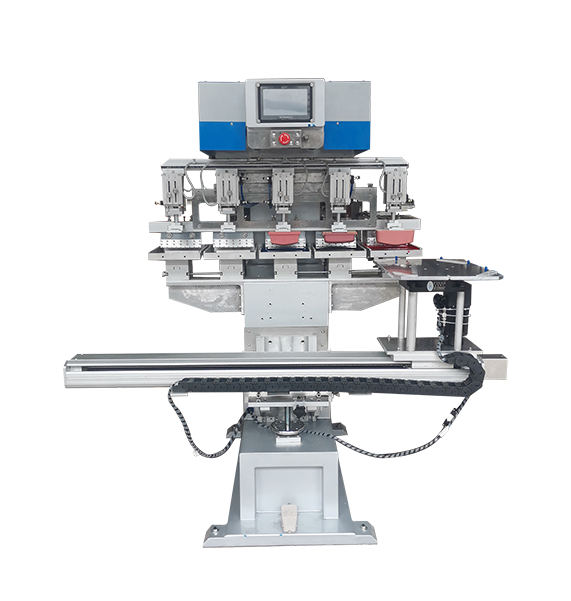

Five-color servo pad printing machine: precise multi-color overprinting, suitable for ultra-large products

- Share

- Issue Time

- Aug 12,2025

Summary

In the field of surface printing for large industrial products, precise multi-color overprinting and the ability to adapt to large volume printing are crucial. The five color servo pad printer, with its servo drive technology and special structural design, can achieve micrometer level printing accuracy and easily meet the printing needs of ultra large products, making it an ideal choice for industries such as heavy machinery and automotive parts.

The precision of multi-color printing comes from the precise control of the servo system. The equipment is driven by a five axis independent servo motor, and the lifting, translation, and pressing actions of each printing color group's glue head are controlled by an independent servo system. The positioning accuracy can reach ± 0.01mm, completely solving the problem of overprinting deviation caused by pressure fluctuations in traditional pneumatic pad printers. For complex patterns such as gradient colors and overlapping colors, the system has a built-in intelligent registration algorithm that captures the positioning marks of the previous color group in real time through a camera, automatically calibrates the printing positions of subsequent color groups, and can control the overall deviation within 0.03mm even if five colors are continuously registered. For example, when printing the company logo and operation signs on the cab panel of large construction machinery, the edges of the five color patterns such as red, blue, and black should be aligned tightly without ghosting or misalignment, ensuring the professionalism of the visual effect.

The core of adapting to ultra large products lies in the breakthrough of equipment structure. The body adopts a modular expansion design, and the printing worktable can be customized according to the product size. The maximum load-bearing area is 2m × 3m, and the load-bearing capacity exceeds 500kg, which is sufficient to accommodate super large workpieces such as excavator counterweights and container side panels. To solve the positioning problem of large products, the equipment is equipped with a 3D visual positioning system, which quickly obtains three-dimensional data of the product surface through laser scanning and automatically generates a printing path. Even if there is slight deformation or placement deviation of the workpiece, it can ensure that the pattern is printed in the preset position. For curved or irregularly shaped ultra large products (such as large oil storage tank heads), a robotic arm linkage device can be selected to allow the transfer printing rubber head to adaptively adjust the angle with the product surface, ensuring uniform printing pressure and avoiding missed printing or pattern deformation.

The efficient and stable printing performance further enhances the production efficiency of ultra large products. The equipment adopts an oil cup ink system, which saves more than 30% of ink compared to traditional oil pan design, and reduces volatile organic compound emissions, suitable for the environmental protection requirements of large workshops. Five color printing can be completed continuously in one go, with a single cycle printing time of only 8-12 seconds, and an hourly production capacity of 300-400 pieces, meeting the needs of mass production. The rubber head is made of high elasticity silicone material, and the hardness (30-70 Shore A) can be customized according to the surface material of the product (such as metal, plastic, composite materials), ensuring complete transfer printing on rough or smooth surfaces.

From the body markings of heavy trucks to the parameter nameplates of large wind power equipment, the five color servo pad printing machine provides an efficient solution for industrial large-scale printing with precise multi-color overlay capability and adaptability to ultra large products, making the surface markings of large products clear, standardized, and visually textured.