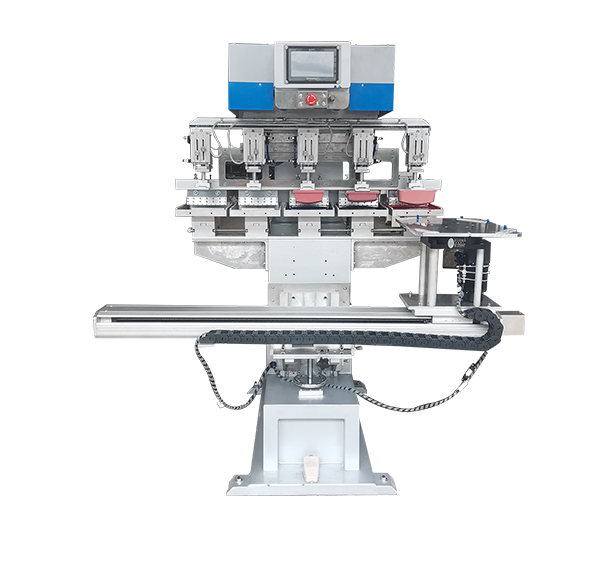

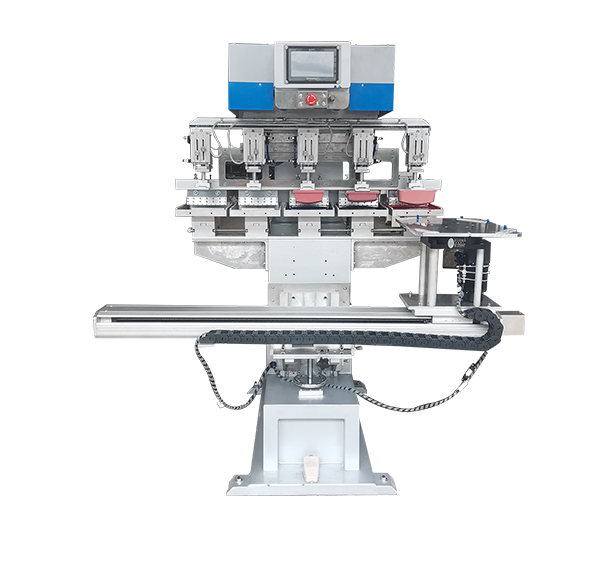

Five color servo pad printing machine: rubber head servo drive, worry free printing of long pieces in multiple positions

- Share

- Issue Time

- Aug 12,2025

Summary

In the multi position printing scenario of elongated workpieces, the driving accuracy and motion coordination of the glue head directly determine the printing quality. The five color servo pad printing machine, with its adhesive head servo drive technology, achieves precise printing control of different positions on long pieces, completely solving the deviation problem of traditional equipment in long-distance and multi-point printing, making the entire long piece printing process worry free.

The adhesive head servo drive system is the core of achieving precise printing. The five printing glue heads of the equipment are equipped with high-precision servo motors, which shorten the driving response time to 0.02 seconds. The movement trajectory, downforce, and dwell time of the glue heads can be adjusted in real time according to the preset program. For the multi position printing requirements of long pieces (such as 1.5-meter-long aluminum profiles and 2-meter-long pipes), the system can use pulse coding positioning to control the movement error of the adhesive head within ± 0.02mm. For example, when printing labels for three different functional areas on the long strip panel of an air conditioning outdoor unit, the adhesive head can accurately locate each printing point in sequence, ensuring that the pattern spacing error does not exceed 0.1mm and avoiding positional deviation caused by long-distance movement.

The efficiency of long piece multi position printing is reflected in process optimization. The equipment adopts an independent working mode of adhesive heads, and the five adhesive heads can work together in a preset order: when the first adhesive head completes the printing of position A, the second adhesive head synchronously starts the printing of position B without waiting for the overall reset, which improves the printing efficiency of multiple sets of patterns on the long piece by 40%. For long pieces that require repeated printing (such as car crash strips produced on assembly lines), the system supports memory storage function, which can save 100 sets of different printing position parameters. When changing the workpiece model, it can be called up with one click, saving time for re debugging. The stroke of the adhesive head can be flexibly set through the touch screen, with a maximum movement distance of 3 meters, which is sufficient to cover the printing range of various long pieces.

To cope with the printing challenges of complex long pieces, servo drive technology demonstrates strong adaptability. For long pieces with uneven surfaces (such as corrugated metal plates), the glue head servo system can provide real-time feedback through pressure sensors and automatically adjust the pressing depth (range 0-5mm) to ensure even ink adhesion at each printing point. When there is slight bending in the long piece, the system's built-in dynamic compensation algorithm will fine tune the trajectory of the glue head according to the actual shape of the workpiece. For example, when printing on a 1.8-meter-long plastic profile, even if the workpiece has a bending deviation of 0.5 degrees, the glue head can still maintain the accuracy of the printing position.

From the long strip components of industrial assembly lines to the long panels of large equipment, the five color servo pad printing machine, with the precision and flexibility of the rubber head servo drive, frees long piece multi position printing from the limitations of traditional equipment, ensuring stable printing quality and improving production efficiency, becoming a reliable choice for long piece printing scenarios.