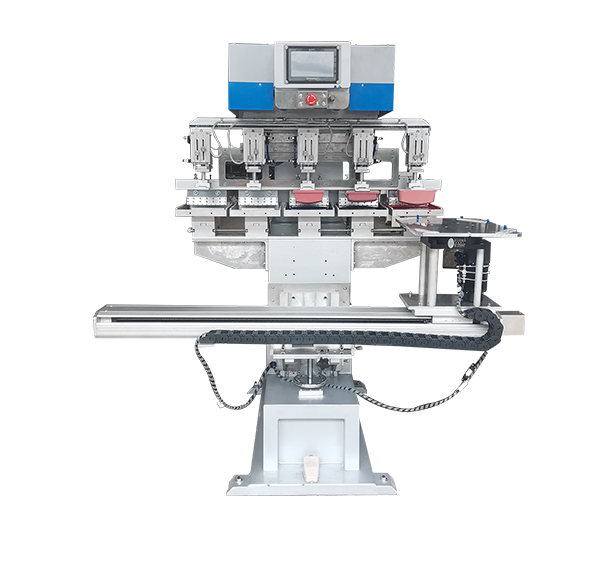

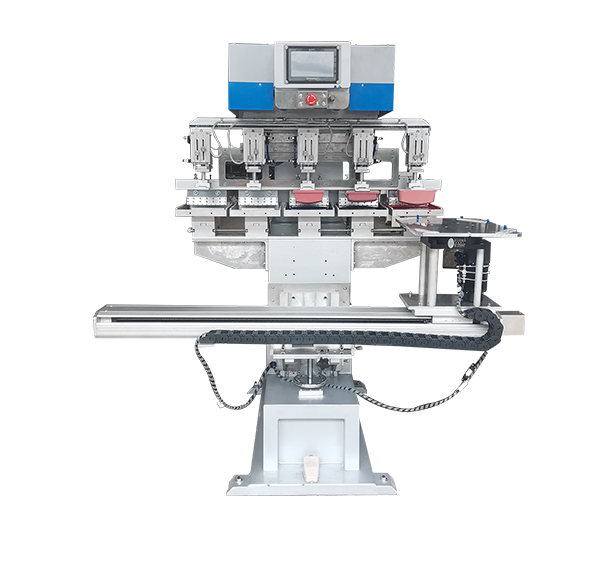

Five-color servo pad printing machine: widely applied across various industries, meeting diverse printing needs

- Share

- Issue Time

- Aug 15,2025

Summary

In modern industrial production, the demand for printing in different industries presents diverse characteristics, from small markings on precision electronic components to complex patterns on large industrial equipment, all of which require highly adaptable printing equipment. The five color servo pad printing machine plays an important role in multiple industries with its flexible functional configuration and strong adaptability, meeting various diverse printing needs.

In the electronic manufacturing industry, five color servo pad printers accurately meet the needs of micro multi-color printing. For small components such as mobile phone buttons and connectors, the device's micro positioning printing system can achieve five color overprinting of 0.5mm × 0.5mm small patterns. The rubber head is made of special micro silicone material to ensure the complete presentation of fine lines and gradient colors. In the identification printing of circuit boards, the equipment is compatible with high-temperature resistant ink. After printing, the pattern remains clear even after reflow soldering at 260 ℃, meeting the reliability requirements of electronic components. For example, when printing multi-color information such as model and parameters on the inner side of a smartwatch case, the device's overlay accuracy is controlled within 0.02mm, perfectly adapting to the strict standards of the electronics industry for details.

The complex printing needs of the automotive parts industry can also be efficiently met. Whether it's the curved steering wheel markings, polyhedral gearbox housing parameters, or high-temperature resistant engine component warning symbols, the equipment can be flexibly adapted through adjustable rubber head modules. The hardness of the adhesive head can be adjusted between 30-70 Shore A. For automotive plastic parts, a low hardness adhesive head is used to ensure adhesion, while for metal parts, a high hardness adhesive head is selected to ensure even printing pressure. In the identification printing of automotive wiring harnesses, equipment combined with specialized ink can achieve anti oil and anti friction effects. Even if it is soaked in engine oil for a long time, the printed pattern will not fall off or blur.

The medical device industry has extremely high requirements for printing safety and clarity, and the food grade ink compatibility and sterile operation design of the five color servo pad printer make it an ideal choice. When printing operation instructions on the handle of surgical instruments, use ink that meets FDA standards to ensure no safety hazards when in contact with the human body; When printing scales and labels on disposable medical supplies such as infusion sets and syringes, the printing accuracy can reach 0.1mm, meeting the accuracy requirements of medical metrology. In addition, the easy to clean structure design of the equipment facilitates regular disinfection, avoids cross contamination, and meets the cleanliness standards of medical device production.

The personalized printing needs of the daily necessities and packaging industry can also be fully met. In the curved printing of cosmetic packaging bottles, the equipment uses a 360 degree rotating worktable to achieve full circumference multi-color pattern printing, supporting complex processes such as gradient colors and laser effects; When printing cartoon patterns on the surface of toys, environmentally friendly and non-toxic ink is used, which has passed EN71-3 standard testing to ensure the safety of children's use. In response to the mass production needs of the packaging industry, the high-speed printing mode of the equipment can complete the five color printing of 800 products per hour, and with the help of an automatic loading and unloading system, achieve unmanned production.

From high-precision electronic components to large industrial equipment, from safety oriented medical devices to colorful daily necessities, the five color servo pad printing machine has become a powerful assistant in improving product identification quality and production efficiency in various industries with its cross industry adaptability and diverse printing solutions, demonstrating strong application scalability and market adaptability.