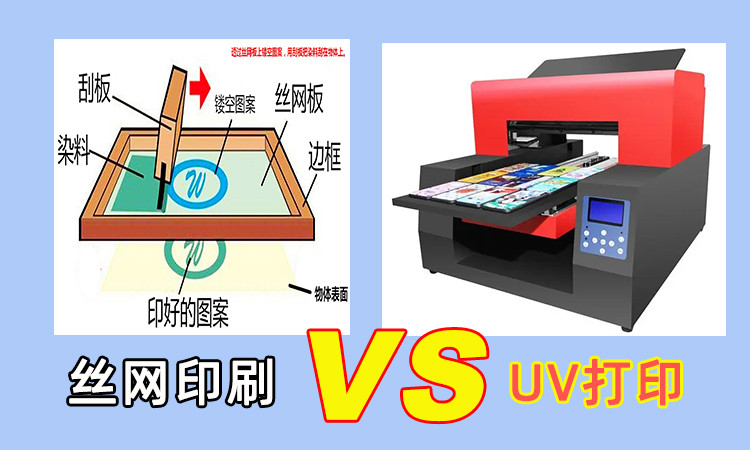

The Difference Between Traditional Screen Printing And UV Printer

- Share

- Issue Time

- Dec 29,2022

Summary

UV is the abbreviation of ultraviolet light, which refers to a way of drying ink in printing, that is, the ink can be cured on the surface of the substrate only after being irradiated by ultraviolet light. Generally, fast drying is required or used when printing on non-absorbent surfaces to...

UV is the abbreviation of ultraviolet light, which refers to a way of drying ink in printing, that is, the ink can be cured on the surface of the substrate only after being irradiated by ultraviolet light. Generally, fast drying is required or used when printing on non-absorbent surfaces to allow ink curing. UV ink can be transparent, which is our common surface glazing. It can also be colored, such as color graphics printed on plastic sheets or metal.

Screen printing is a printing method that transfers ink to the substrate through the holes of the screen plate. Ink can leak through the places with graphics and text, and the holes in the blank areas are sealed to prevent ink leakage to complete the transfer of graphics and text. Compared with offset printing and gravure printing, screen printing has lower precision, but the cost is also lower. And because the substrate can be placed flat during printing, the substrate has a wide range of adaptability, such as soft textiles or mobile phone cases with thickness and uneven surface.

The surface glazing mentioned above, that is, to print a layer of transparent and bright material on the surface after color printing, is all made of UV varnish, and usually does not need to print too fine dots, so most of them use lower cost Finished by screen printing. So UV and screen printing are still related.

There are three main differences between uv printers and screen printing:

1. Comparison of environmental protection

Silk screen printing is a traditional printing process, which is very harmful to the production environment and the external environment. The unpleasant smell and waste ink discharge are serious pollution.

The uv printer uses a new type of uv ink, which is green and environmentally friendly, and has extremely low harm to operators and the environment.

2. Cost comparison

Traditional screen printing requires film plate making, which costs 200 yuan per plate, complicated process and long production cycle. It can only print monochrome printing. The cost of printing is relatively expensive, and the well-made screen printing dots cannot be eliminated. Mass production is required to reduce costs, and printing of small batches or individual products cannot be achieved.

UV is a short-run printing that does not require complex typesetting design or plate making, and is suitable for various types of personalized printing. There is no minimum quantity limit, which reduces printing costs and time. Only simple image processing is required, and after calculating the relevant values, directly use the uv printing software to operate.

3. Process comparison

The screen printing process is relatively complicated, and the plate-making and printing processes are selected according to different printing materials. There are many types of specific processes. As far as the color set is concerned, a rich designer's understanding of colors is required. One color is one plate, and the overall operation is troublesome. .

The UV printer only needs to place the printed material on the platform, fix the position, and perform simple typesetting and positioning of the processed high-definition pictures in the software, and then start printing. The printing mode is consistent for different materials, but a small number of materials need to be coated.