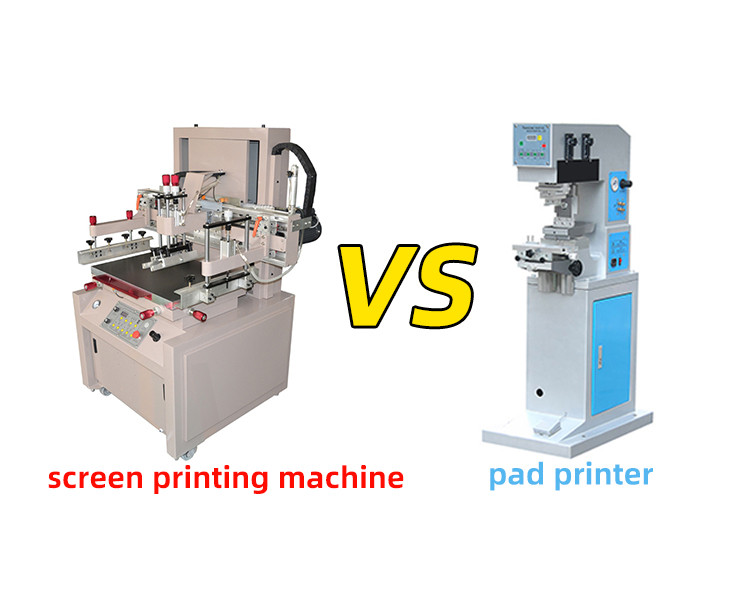

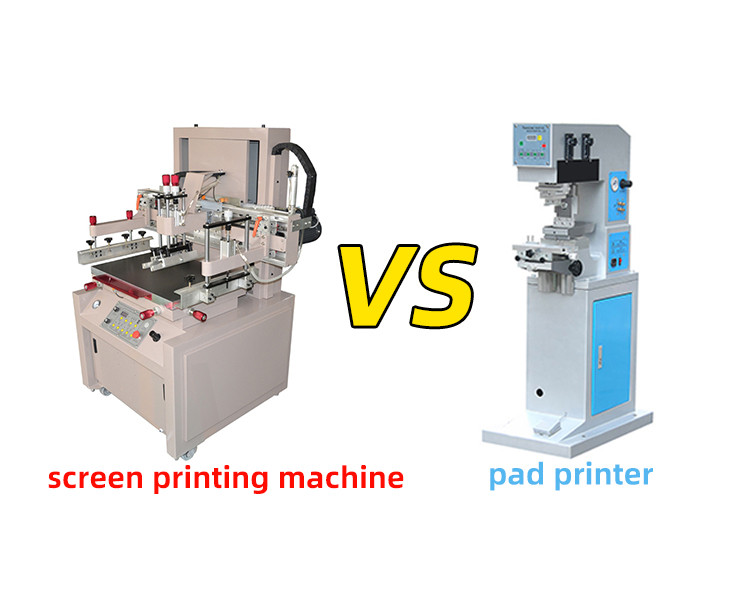

What are the differences between screen printing machines and pad printer?

- Share

- Issue Time

- Feb 24,2024

Summary

Introduction: In the printing industry, screen printing machines and pad printer are common printing equipment, but what are the differences between them? Today, let us discuss the differences between screen printing machines and pad printer!

1. Differences in working principles

Screen printing machine: The screen printing machine uses screen printing. Through the scraping pressure of the scraper, the ink is transferred to the substrate through the mesh of the screen printing plate. This printing method is suitable for printing large areas and thick ink layers.

Pad printing machine: The pad printing machine uses a silicone head to transfer the ink on the gravure plate to the substrate. It is suitable for small-area, high-precision, multi-color printing.

2. Differences in application scenarios

Screen printing machine: Screen printing machine is widely used in electronics, ceramics, glass, textile and other industries, especially suitable for large-volume, high-efficiency printing needs.

Pad printing machine: Pad printing machine is more commonly used for surface printing of plastics, metals, rubber and other materials. It is especially suitable for small pieces, special shapes, curved surfaces and other objects that are difficult to print directly.

3. Comparison of operational convenience

Screen printing machine: The operation of the screen printing machine is relatively simple, but it requires certain skills and experience, especially in adjusting the screen plate, scraper, etc.

Pad printing machine: Pad printing machines are more intelligent, automated, and easy to operate, reducing the skill requirements for operators.

4. Cost-benefit considerations

Screen printing machine: The initial investment cost of a screen printing machine is relatively low, but due to the large number of consumables in the printing process, the later costs may be higher.

Pad printing machine: Although the initial investment cost of a pad printing machine is relatively high, it is highly cost-effective in the long term due to its high printing accuracy and wide range of applications.

Conclusion: Through the above analysis, we can see that there are obvious differences between screen printing machines and pad printing machines in terms of working principles, application scenarios, ease of operation and cost-effectiveness. Therefore, when choosing printing equipment, you need to choose the appropriate equipment based on actual needs and scenarios.