Summary

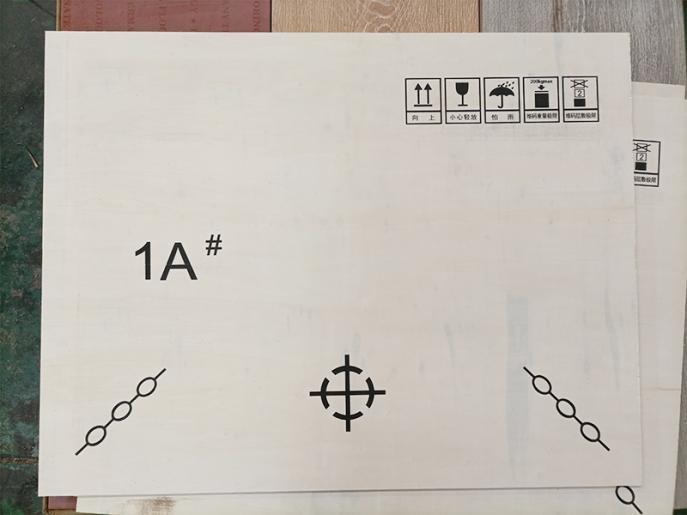

Semi-automatic flat screen printers have demonstrated excellent performance in wooden box packaging logo printing, and their process features include high precision, wide adaptability and high efficiency

Summary

Semi-automatic flat screen printers have demonstrated excellent performance in wooden box packaging logo printing, and their process features include high precision, wide adaptability and high efficiency