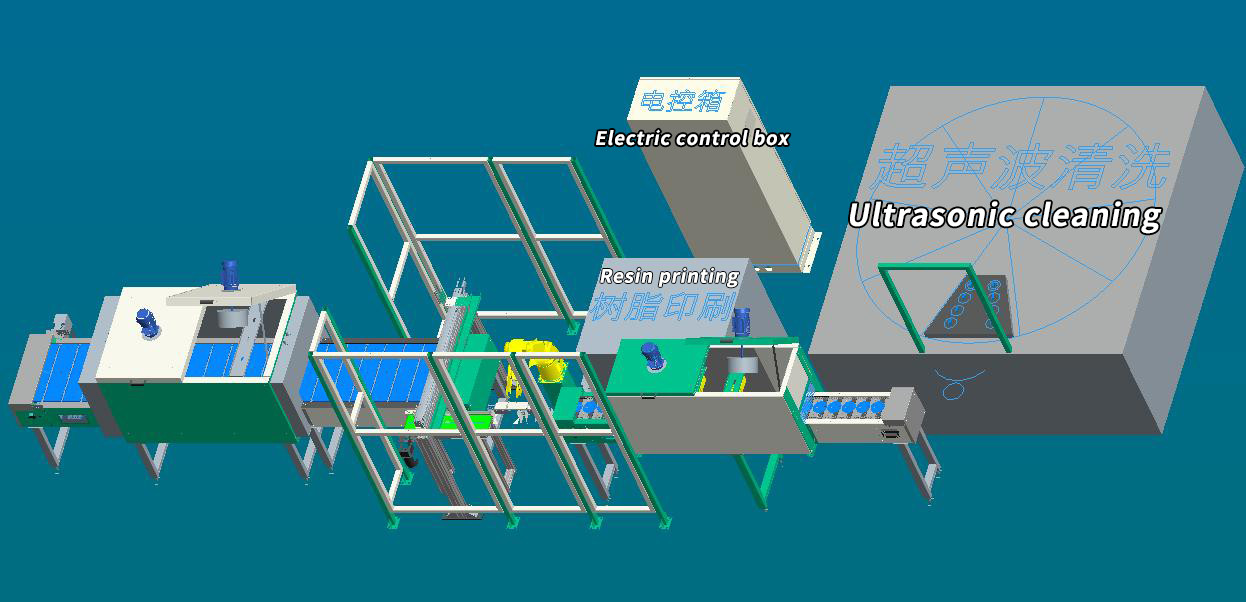

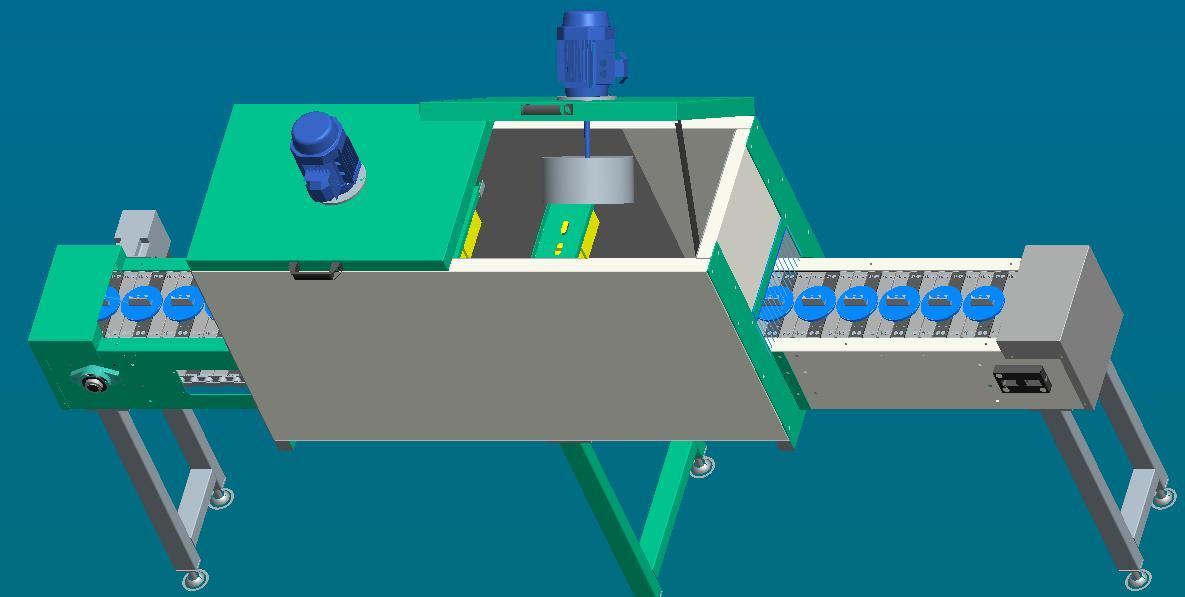

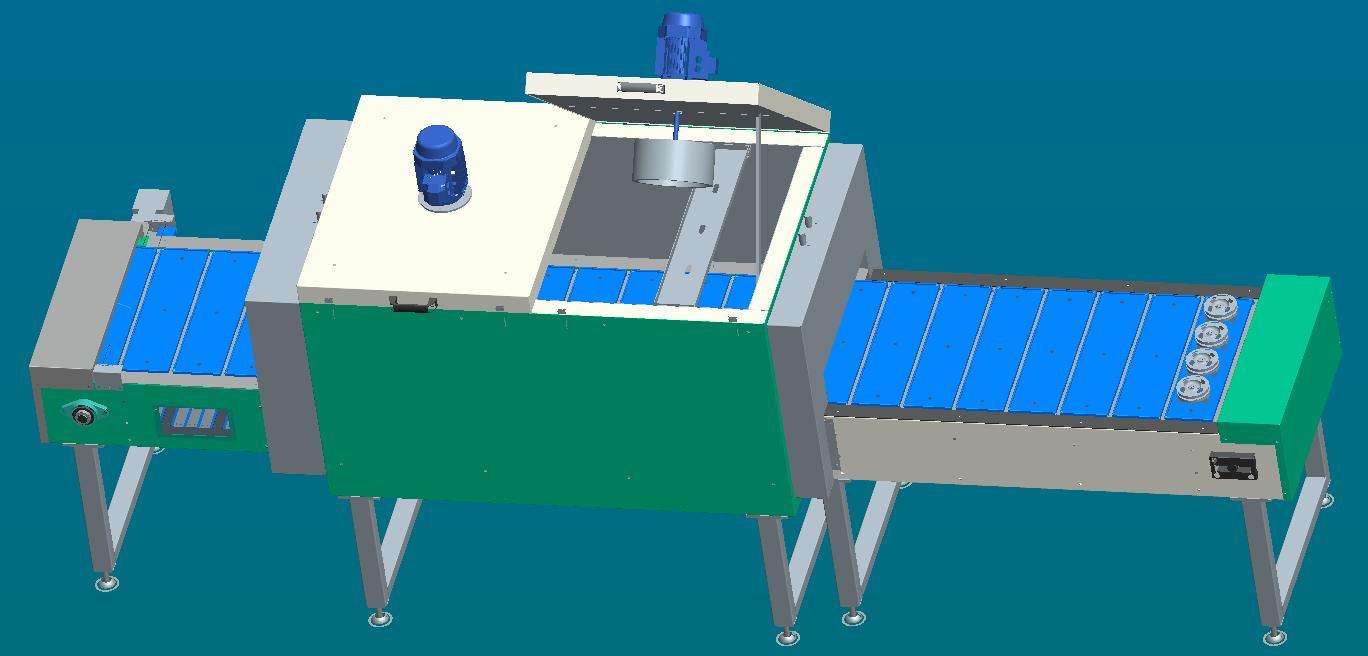

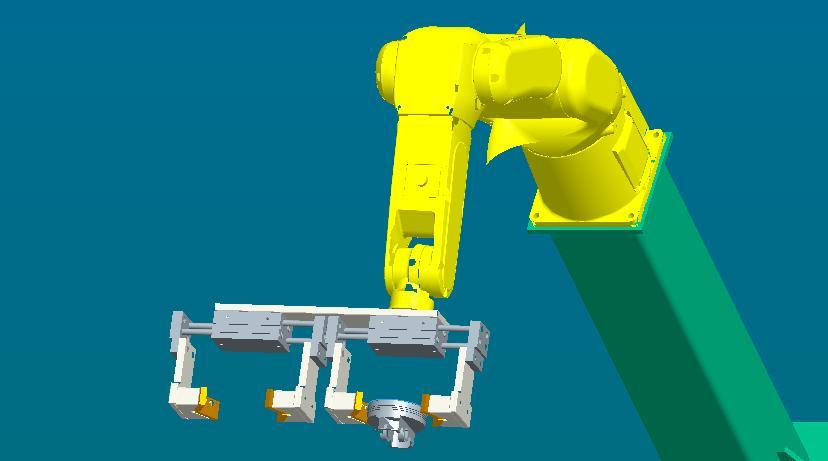

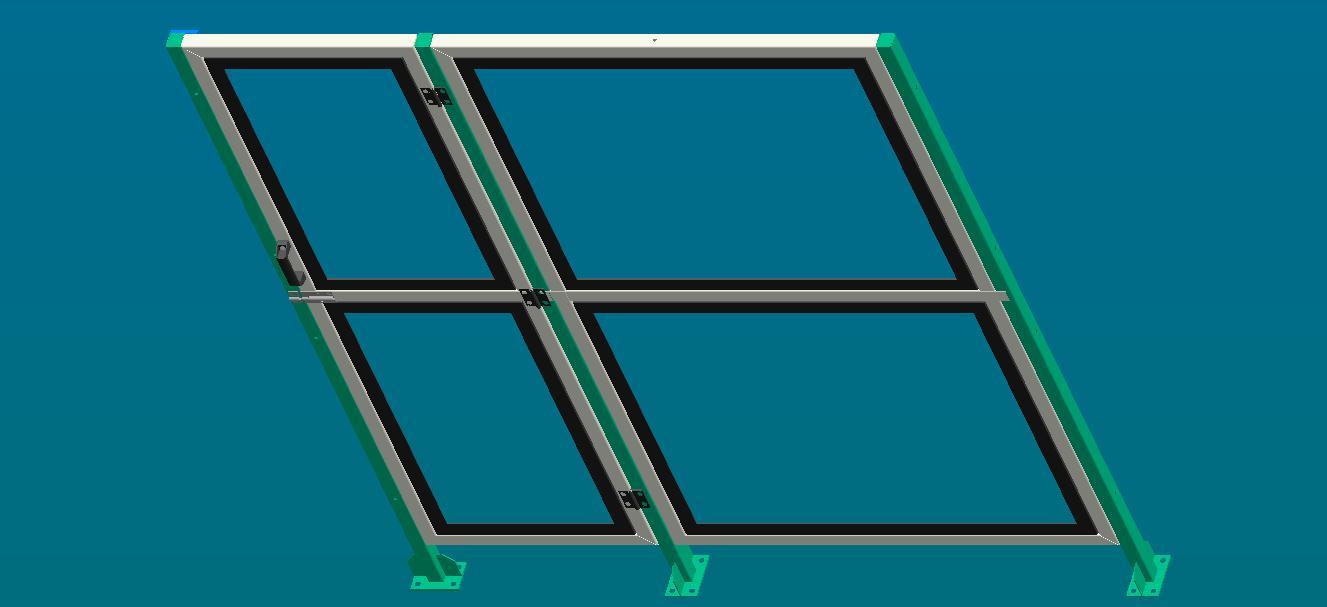

1. The equipment includes cleaning machine, resin printing machine, drying line A, drying line B, belt line, handling mechanism, handling robot, protective fence, electric control box and other components . The general layout is shown in the figure below ; ( The dimensions in the figure are for reference only)

2. Cleaning machine: ultrasonic cleaning is adopted; the equipment is divided into 9 stations, NO1 manual loading/unloading station, NO2 ultrasonic rough cleaning, NO3 spray cleaning, NO4 ultrasonic fine cleaning, NO5 municipal water spray rinsing, N06 pure water spray rinsing, NO7 pure water spray rinsing, NO8 wind blowing water cutting, NO9 hot air drying ; the products are placed on the bracket, each bracket can hold 8 products, the cylinder drives the bracket to rise and fall, and the divider mechanism realizes the rotation and circulation of the products between the 9 stations;

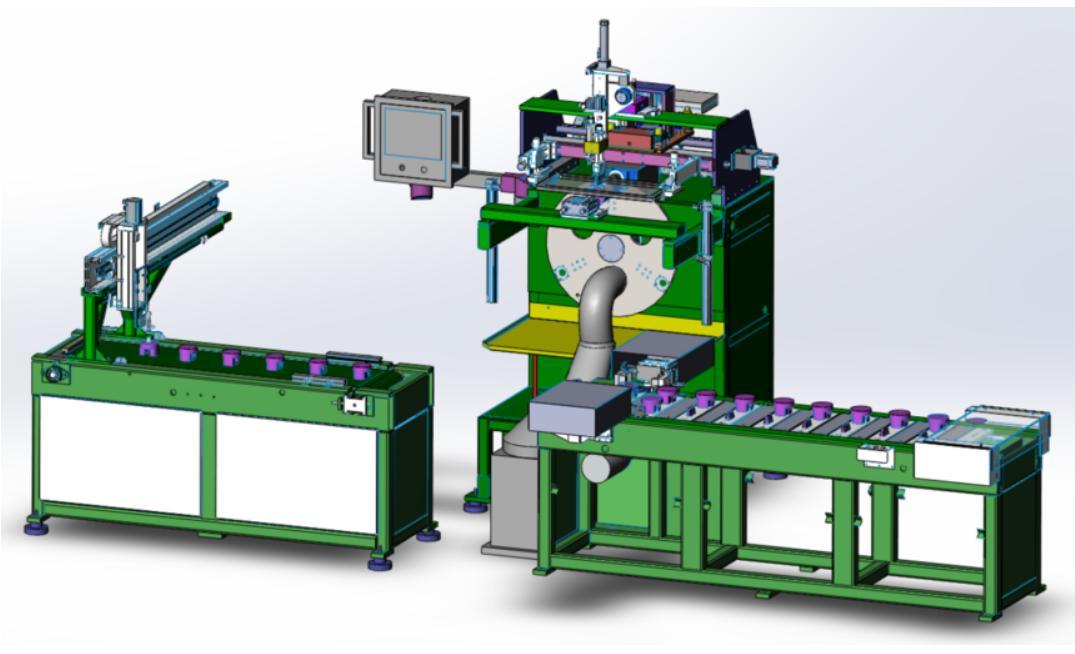

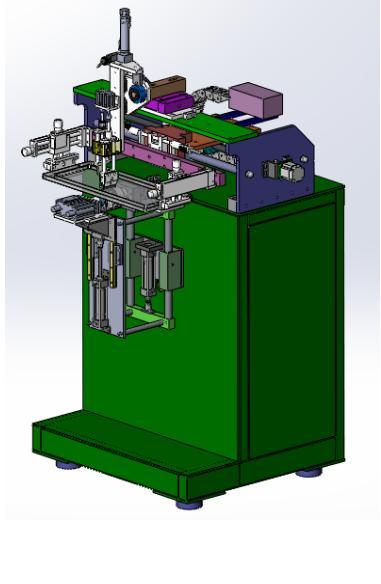

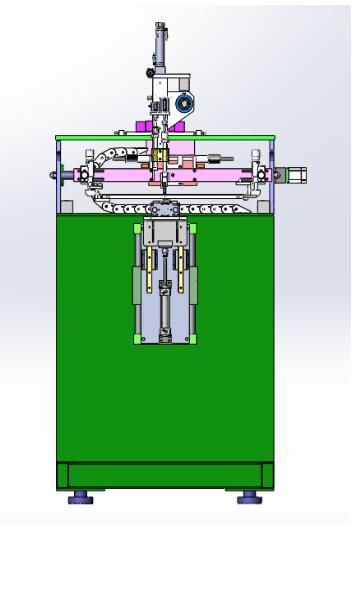

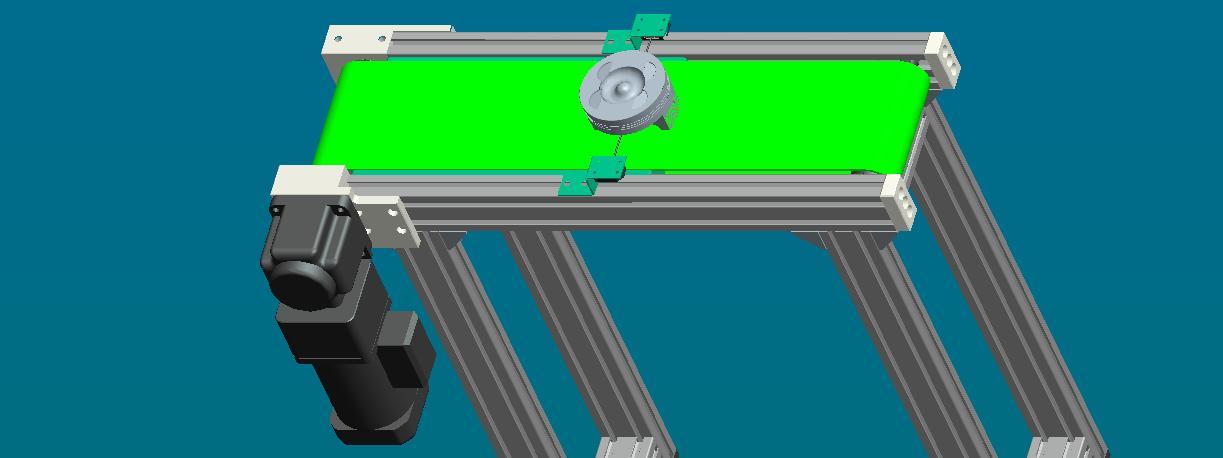

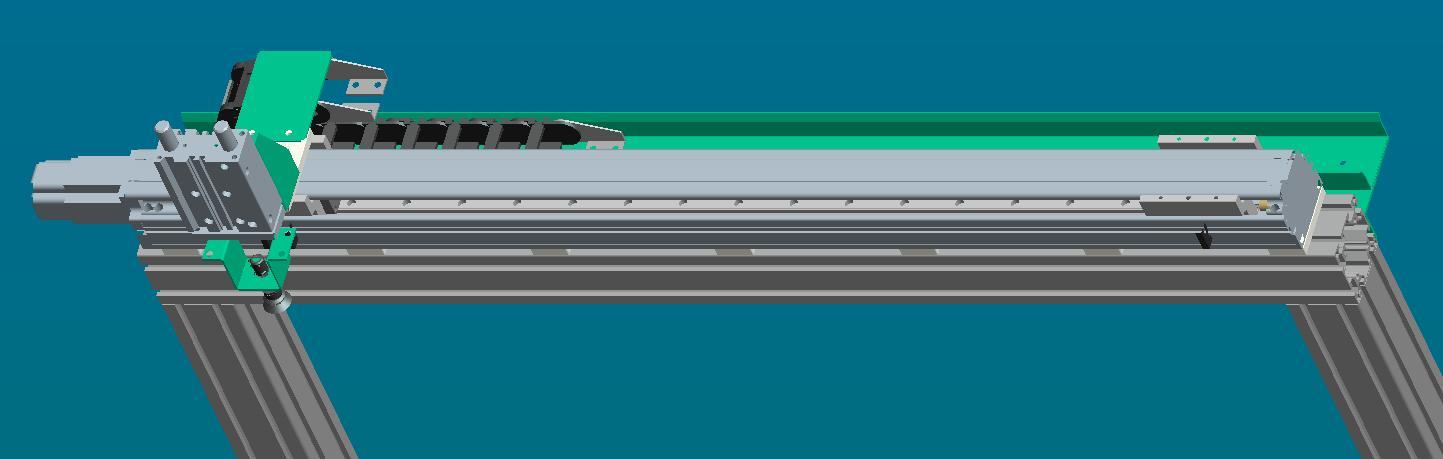

3. Resin printing machine: printing the outer circumference of the piston;