Summary

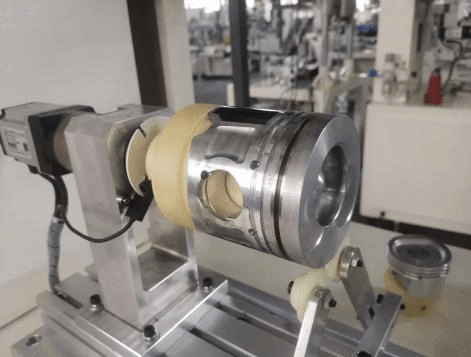

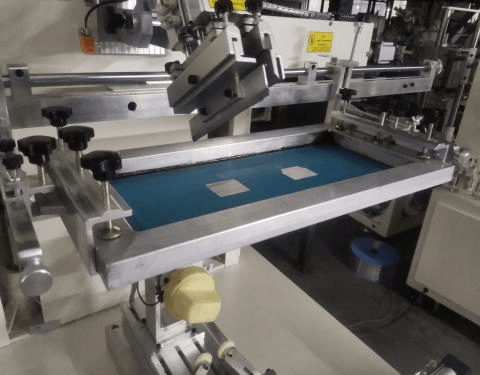

The piston is one of the key components of the internal combustion engine, which directly affects the performance and efficiency of the engine.

Summary

The piston is one of the key components of the internal combustion engine, which directly affects the performance and efficiency of the engine.