Hot Melt Powder Coating Machine For Heat Transfer Stickers

- نموذج

- TX-SF80S

ممتلكات

- Transmission belt width

- 800mm

- Width of Power coating

- 650mm

- Thickness of material

- 1~5mm

- Voltage

- AC380V/ 220V

- Weight

- 3500KG

- Application area

- plastic film , label roll

- MAX. POWDER COATING

- 2 Kg/㎡

- POWDER RANGE

- 60-300 m

- MAX. BELT SPEED

- 20m/min

تقييم

وصف

The hot melt powder coating machine is a post-printing equipment that replaces the traditional manual hot melt powder sprinkler. It is suitable for the hot melt powder sprinkler process on transfer products such as clothing trademarks, heat transfer, wallpaper, paper, film, etc. It has the function of powder sprinkler and residual powder recovery in one go, and is easy to use, flexible to adjust, high in work efficiency, and free of dust pollution. All transmission parts of the machine are frequency-controlled and can be directly connected to the fully automatic screen printing machine, achieving perfect results for the hot melt powder sprinkler process on paper, film, wallpaper, etc. with high surface requirements. If required by the process, the drying equipment can be directly connected to the back of the machine.

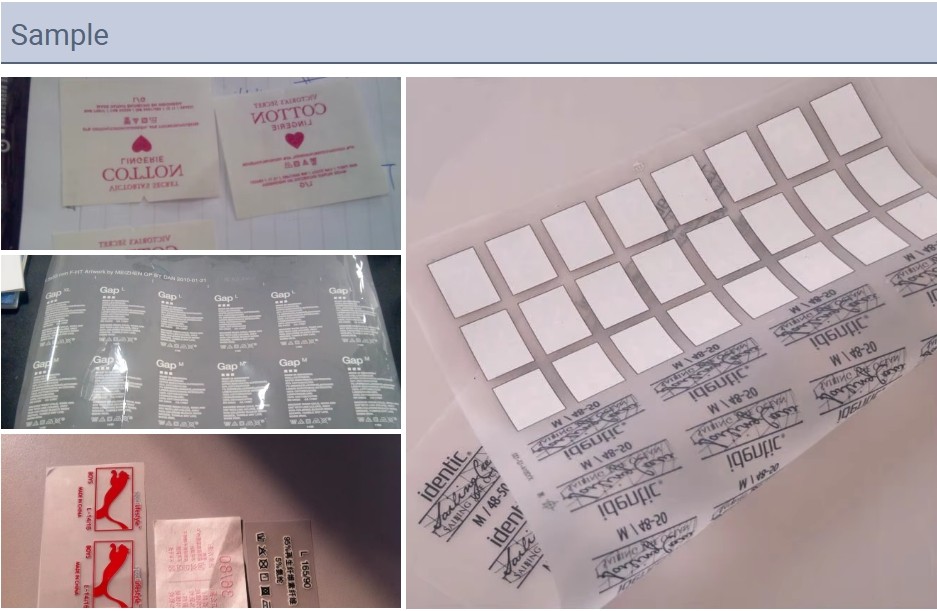

★Application

Product parameter

| Model: TX-SF80S |

Belt width: 800mm |

|---|---|

| MAX. SHEET WIDTH: 600MM |

MAX. THICKNESS: 5MM |

| MAX. POWDER COATING: 2 Kg/M2 |

POWDER RANGE: 60-300 m |

| TOTAL POWER: AC380V / 4.1KW |

RATED VOLTAGE: AC380V , |

| MAX. BELT SPEED: 20m/min |

Weight: 3500KG |

★MAIN FEATURES: