TAOXING Semi-Automatic Flat Screen Printer TX-4050T For PCB Boards and SMT Patch Solder Paste Printing

- نموذج

- TX-4050T

تقييم

وصف

Introduction

Application

This semi-automatic flat screen printing machine is suitable for stencil printing of products such as PCB and SMT solder paste in the electronics industry.The semi-automatic paste screen printer boasts efficiency gains with automated processes, ensuring precise application of solder paste. It enhances productivity, reduces human error, and adapts easily to diverse PCB layouts, making it a cost-effective solution for electronics manufacturing.

Specification

Product name: Semi-automatic solder paste printer

Product model: TX-4050T

Printing table area: 500×700mm

Screen frame suitable size: 370*470-550*900mm

Suitable substrate size: 15*15-400*340mm

Scraper speed: 0-100mm/s

Substrate thickness: 0.3-5mm

Printing accuracy: L±10mm

Printing position fixation: PCB Outer Or Pin Positioning

Plate fine-tuning: ±10mm

Machine repeatability: ±0.02mm

Minimum spacing: 0.35mm

Air pressure: 4-6kgf/cm2

Power supply: single-phase 220V, 5060HZ, 100W

Machine size: L900×W105×H1650mm

Machine weight: about 250kg

Main performance

(1) The suspended scraper system makes printing more flexible. The scraper can float up and down freely and automatically adjust to the level of the steel mesh;

(2) The scraper seat can be adjusted forward and backward to select the appropriate printing position;

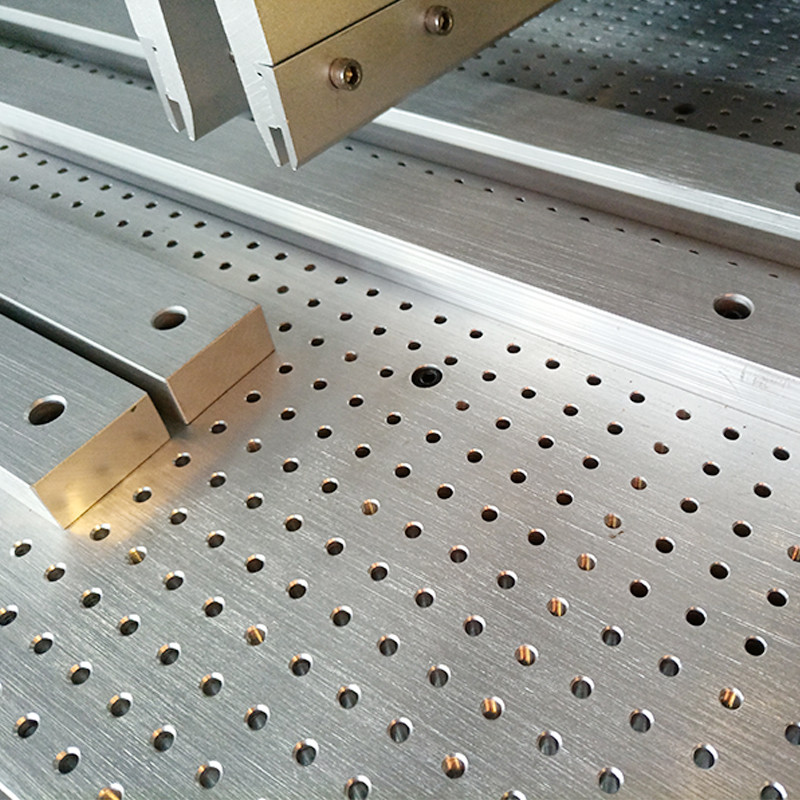

(3) The combined printing table has fixed grooves and PINs, which are easy to install and adjust, and are suitable for single- and double-sided printing;

(4) The workbench is equipped with a honeycomb aluminum plate, support strips, and a pin with a reference hole positioning pin structure, which is convenient for single- and double-sided printing of PCB boards of different specifications;

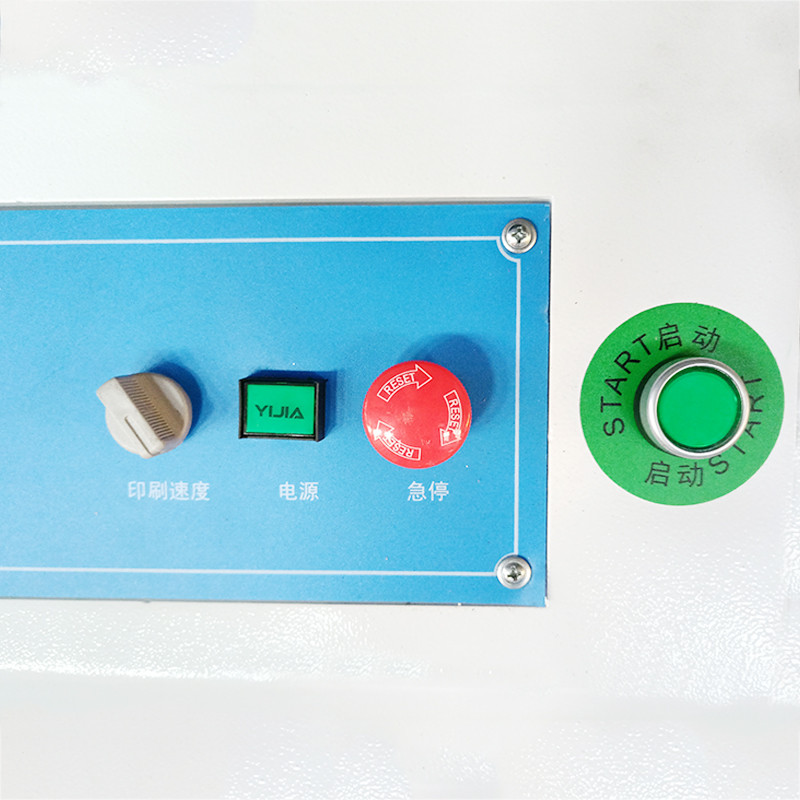

(5) It has automatic, semi-automatic and There are three working states of inching. Inching is mainly convenient for trial printing and adjustment at the beginning;

(6) The calibration method adopts steel mesh movement and combines the X, Y, and Z of printing (PCB), which makes correction and fine-tuning convenient and fast;

(7) Industrial product computer PLC control and human-machine interface are simple, convenient and more suitable for human-machine dialogue;

(8) It has automatic counting function, which is convenient for production output statistics;

(9) The scraper angle is adjustable, suitable for steel scrapers and rubber scrapers;

(10) The printing machine speed human-machine interface digital display can be arbitrarily adjusted and controlled digitally.

Machine image

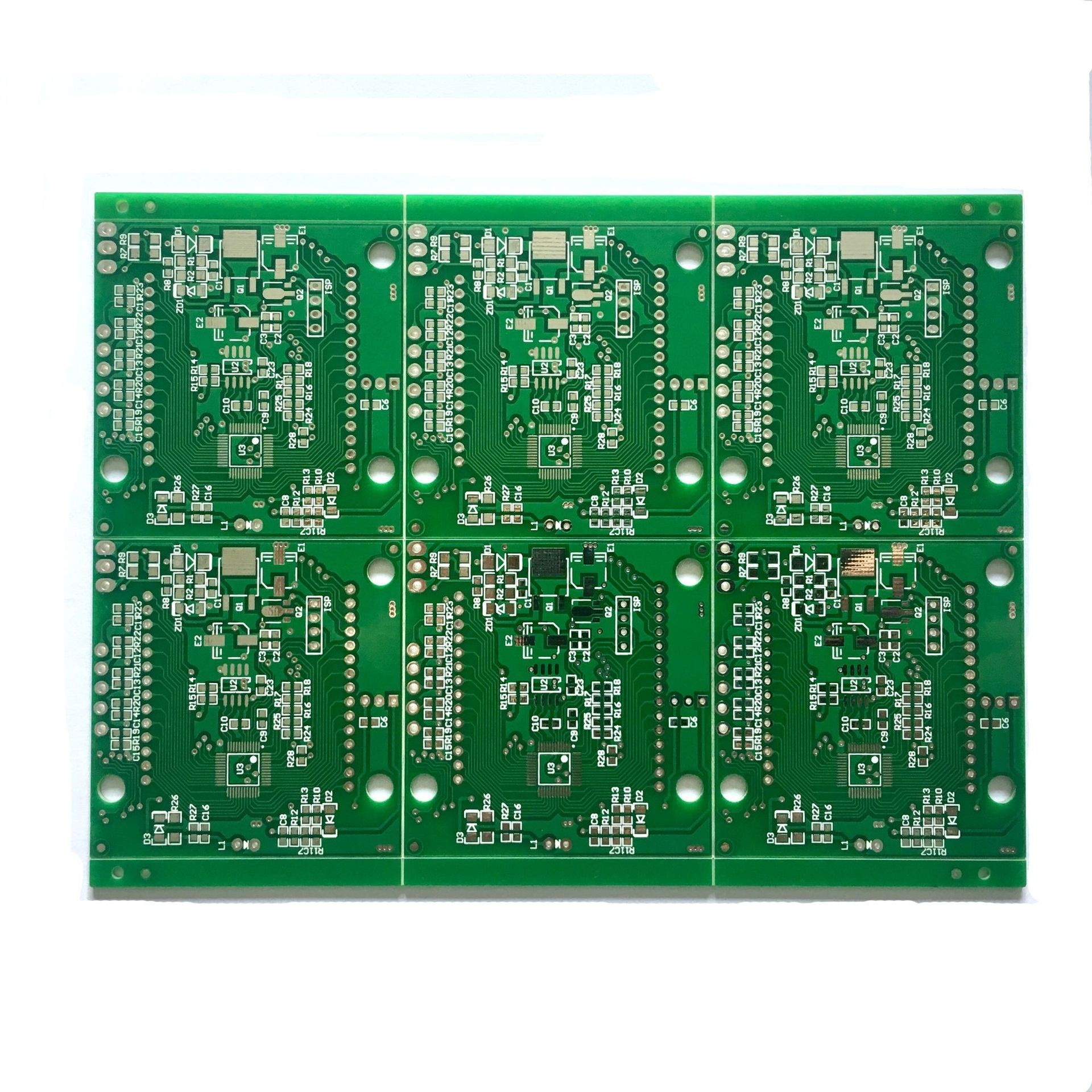

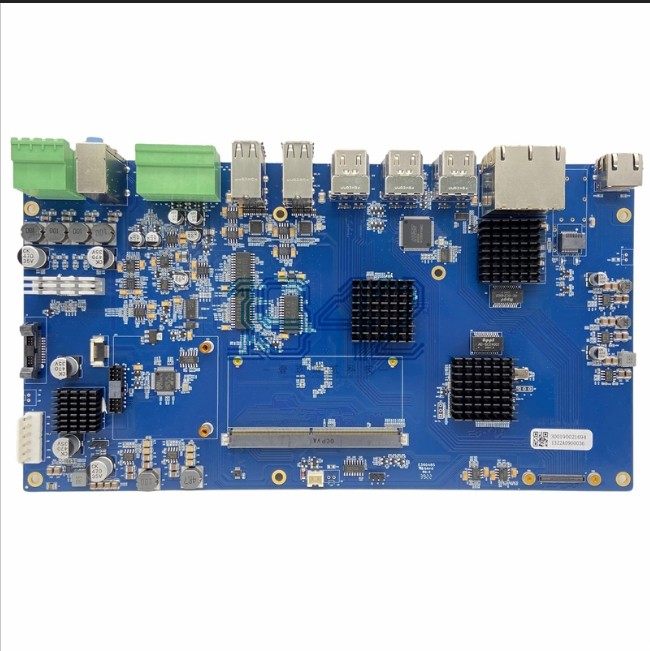

Printing samples