TX-250A-CCD Semi-automatic Thick Film Screen Printing Machine

- نموذج

- TX-250A-CCD

ممتلكات

- Printing size

- 250*250mm

- Printing table size

- 350*350 mm

- Max Screen frame size

- 550*550*25mm

- Height from platform to ground

- 950mm

- Scraper stroke

- MAX 390m

- Scraper speed

- 5~ 350mm /sec

- Printing pressure

- 0.005 ~ 0.5MPa( adjustable )

- Grid distance

- 0~20mm

- Parallelism between scraper and platform

- Within 0.01mm

- Power supply capacity

- AC220V 3.5KW

- Machine weight

- About 750kg

- Machine size

- 1400 × 1100 × 1850mm

تقييم

وصف

Introduction

Application:

Widely used in touch screen circuits and BM printing, ceramic capacitors, resistors, thick film circuits, ceramic circuits, filters, glass glaze potentiometers, dielectric antennas, ceramic metallization, RFID, sensors (piezoresistive, capacitive) integrated LED lamp holders, piezoelectric ceramic components, LED ceramic substrates, LTCC, MLCC, filters, ceramic thick film circuits, solar silicon wafers, chip components and electronic component printing process manufacturing. (It can realize buried hole printing and through hole printing)

Specifications

Platform size: 350*350 mm

Max screen printing size: 550*550*25 mm

Work height / table height:950 mm

Table movement accuracy: 0.005mm

Parallelism between frame botlom and platform: Within 0.02mm

Printing capacity: 5~ 350mm /sec

Air source: 0.6-0.8 MPa 50L / min

Power supply: AC220V 3.5KW

Weight: 750kg

Machine size: 1400×1100×1850mm

Features

1. The printing platform X, Y, θ automatically aligns the “+”, “o” and “ outline ” marks for printing through CCD;

2. This machine is a standard thick film circuit printer, the main features of which are ease of use, high efficiency and high precision;

3. The whole extrusion casting of the machine head adopts full motor design, and the running table, scraper, printing and vacuum are all driven by motors;

Performance:

A.Power mode: Printing pressure, printing frame drive and platform drive use independent power sources and PLC control.

B.Overall structure - the machine body is welded with die-cut steel, the upper surface is overall flat-ground with an accuracy of ± 0.05 , and the head unit is integrally cast.

C.Grid system:

Grid structure—— the grid arms are locked on the overall frame, which is compact and safe.

Grid lifting———— Manual precision adjustment of the grid and platform grid distance lifting, adjustable (0~ 20mm ).

D. Printing system:

Printing guide———— Use Taiwan TBI screw , 10 lead.

Printing/flooding speed – digitally entered and independently adjustable.

Printing stroke————The stroke is set digitally on the touch screen (1~ 390mm ) .

Printing drive————Japanese servo system, screw drive; no creeping at low speed, no jitter at high speed.

Scraping pressure———— controlled by back pressure , Eliminate the scraper's own gravity and precisely control the pressure printing.

E. Platform system:

Platform structure———— U VW platform displacement accuracy ±0.0 05 .

Platform drive——The linear module drives the platform to move forward and backward, with a positioning accuracy of ±0.0 05 .

F. CCD Vision System:

Lens —————— 28 mm OPT lens

Industrial computer ———— PC

Monitor———— Dell 1 7- inch

Image acquisition method : two sets of 5 million pixel CCD digital cameras

Detailed Images

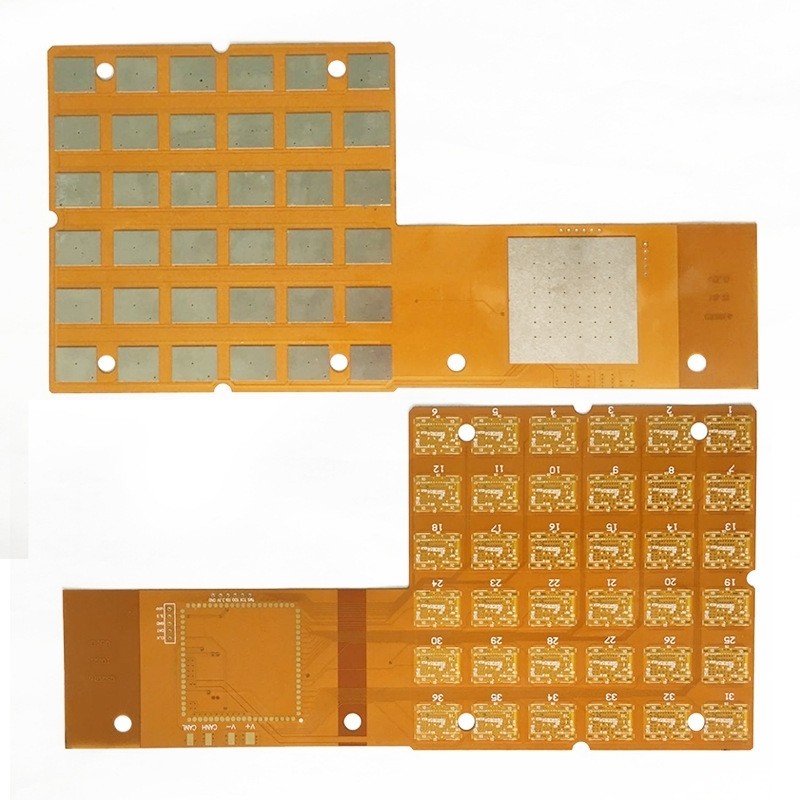

Printing samples

Technical Service

1.After-sales service methods: regular or irregular visits for maintenance, operation and technical training.

2.After-sales service costs: During the warranty period, our company will bear the cost; after the warranty period, our company will charge for accessories.

3.Service Content:

A.If there are any quality problems with equipment accessories, they will be replaced free of charge within two years.

B.We have a thick film printing proofing workshop, which can provide customers with pre-sales and after-sales proofing services.

C.If the equipment fails and the problem cannot be solved through telephone communication after receiving a phone call , our company will arrive at the site within 24 hours to solve the problem .

D.After-sales service is not only about equipment repair and maintenance, but also includes full and dedicated support for process technology. Our company's process technicians can conduct on-site technical training and provide a full set of thick film printing process technology, information and equipment solutions .