Aluminium Alloy Graphite Piston Printing Machine TX-500SS

- Model

- TX-500SS

Item specifics

- Max printing area

- 500*200mm

- Max frame size

- 700*350mm

- Printing speed

- 600 - 800 pcs/h

- Substrate Diameter

- 10-160mm

- Air pressure

- 5bar

- Max substrate length

- ≤300mm

- Dimensions(L*W*H)

- L1500* W1200mm* H1540mm

Review

Description

Introduction TX-500SS Servo curved screen printing machine

Our servo cylindrical screen printing machines are well designed for do multi-color overprint on the round product printing round, oval, square and other special shape containers.

Main parameters

Model:TX-500SS

Product Diameter: 10-160mm

Air pressure: 5bar

Voltage/Power: 220V/50HZ/500W

Max printing speed: 800(PCS/H)

Max frame size: 700*300mm

Max printing size: 500*200mm

Max product length: ≤300mm

Features:

Compared with ordinary curved surface color registration, it is more convenient that it does not require positioning points, and the infrared light eye has higher positioning and color registration accuracy, which is suitable for enterprise product development and small batch printing.

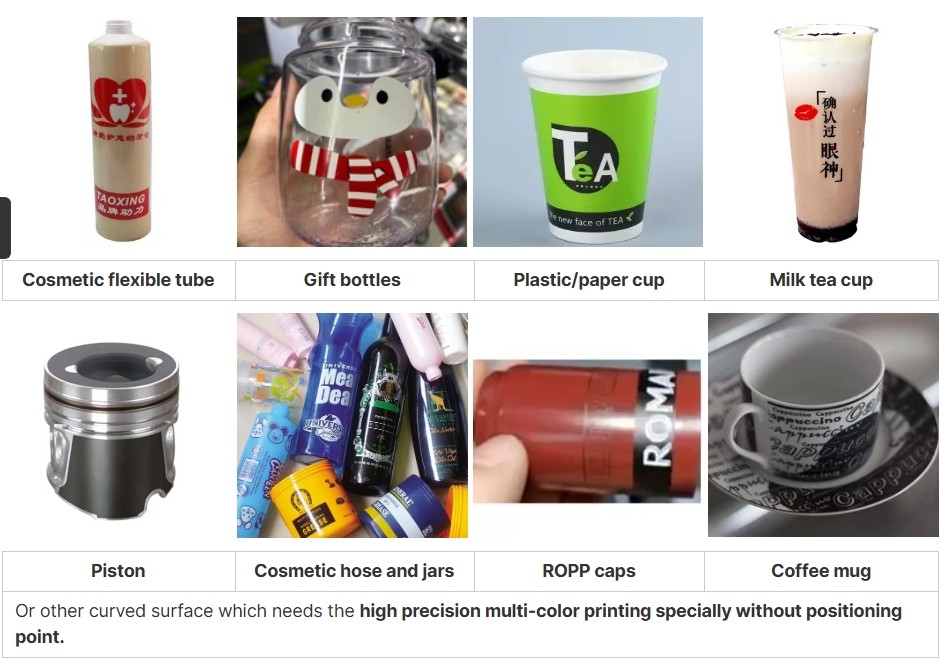

This screen printing machine is available to print on plastic, glass and metal goods, like cups, plastic bottles, glass bottles, pistons, bottle ROPP caps, jars, plastic flexible cosmetic soft tubes and so on. Widely used for industries of daily chemical, food,beverage, pharmaceutical, chemical, personalized water bottle business, cosmetic bottle manufacture, etc.

Main performance

1. PLC programming, touching screen, simple to operate, easy to use

2. Built in digitalcounts for production output

3. Facilitate to placement of the productbenefit from special design famous air cylinders

4. Servo motor drive rotating and printing head ensure high precision

5. Self-balance scraper technology and ink cover blade

6. Printing Strokeand rotation by digital adjustments, printing speed controllable.

7. Convenient operating the height of the printing beam by hand wheel.

8. Easy to disassemble and cleaning the screen plate due to the independent design of lifting printing head including scraper and squeegee;

9. Quality photoelectricity sensor and perfect fault self-detect

10. Metal structure,running steady, foot switch for starter.

Application

Cooperative Customers