Vertical Pneumatic Flat Screen Printing Machine TX-3050S For Metal Nameplate

- Model

- TX-3050S

Item specifics

- Printing color

- 1 color

- Operating mode

- semi-automatic

- Printing speed

- 500- 1000pcs/h

- Maximum mesh frame size

- 300*600 mm

- Printing size

- 300 * 400mm

- Voltage / power

- 220V 380V/50HZ /2.1KW

- Dimensions

- 650*700*1500mm

- Printing Thickness

- 0-100mm

- Table size

- 300 * 500mm

- Gross weight

- 110KG

- Printing pressure

- 4.0~6.0 kfg/c㎡

- Packing size

- 850*650*1600mm

Review

Description

Application

Small flat suction screen printer uses a vacuum generator to generate suction force, is noiseless, has strong adsorption force, and completely replaces manual screen printing, solving the problems of unstable hand printing quality and slow printing speed. It has a compact appearance, fast running speed, stable performance, and high precision. It can form a screen printing production line in a smaller factory space, and is especially suitable for screen printing of surface patterns on PVC films, paper, nameplates, and various films.

Specifications

|

Model: TX-3050S

|

Printing area: 300*400mm

|

Platform size: 300 * 500mm

|

|

|

Printing thickness: 0-100mm

|

Printing accuracy: ±0.02mm

|

Maximum screen frame: 300*600 mm

|

|

|

Printing pressure: 0.5-0.7Mpa

|

Power supply: 220V/50HZ/50W

|

Maximum printing speed: 500- 1000pcs/h

|

|

|

Gross weight: 110(KG)

|

Machine size: 650*700*1500mm

|

Packing size: 850*650*1600mm |

|

Features

1. Microcomputer control has high automation and simple operation.

2. Use imported pneumatic components from famous manufacturers, with reliable performance.

3. Dual-mode selection of oil return scraper to meet various printing requirements.

4. The printing stroke and speed are adjustable to meet different printing requirements.

5. Automatic balancing scraper can ensure balanced printing pressure.

6. Imported shaft and sleeve are used to make the screen scraper slide smoothly for printing.

7. The running speed of the sliding parts can be adjusted independently, making it more convenient and quick to use.

8. High printing precision, convenient and quick adjustment.

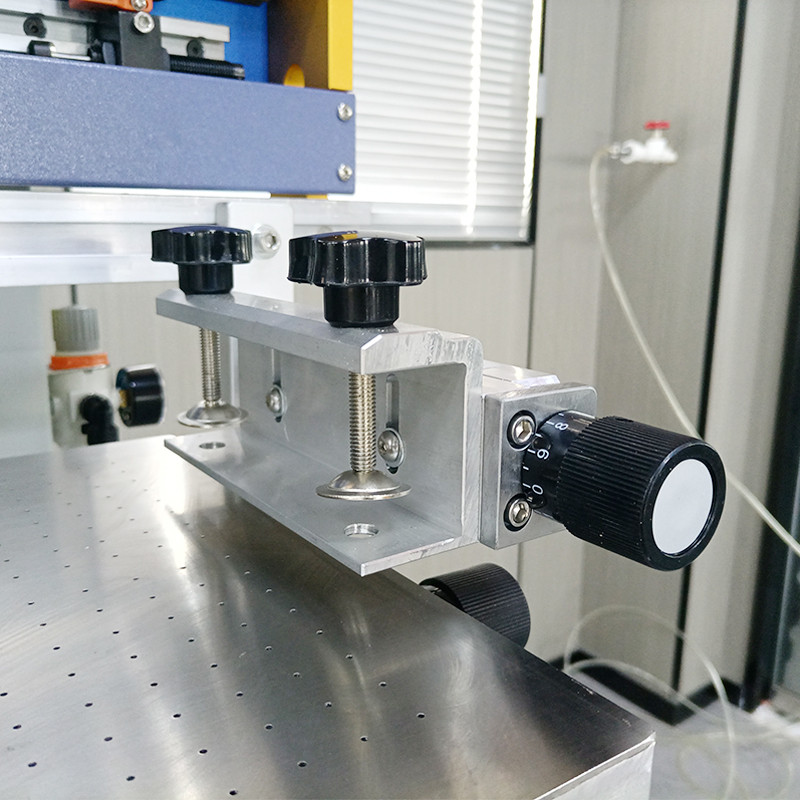

Machine Details Display

Printing Samples

Configuration Instructions

①Microcomputer control with stable and reliable performance

②High -quality sensors

③Convenient and simple foot switch control

④International brand pneumatic components

⑤Advanced air filtration device

⑥Sturdy parts

⑦ Wear-resistant imported shaft sleeve

⑧Independent printing and ink return speed control

⑨Easy to operate and maintain

Machine Maintenance

① Before going to work, you should clean up the debris on the machine and wipe it clean. Regularly add lubricating grease to the guide rails, guide columns, bearings and other moving parts.

② The work table is a key component that affects the printing quality. It should be prevented from being hit by hard objects. When printing, ink, thinner and other organic solvents should not be dripped onto the work table.

③ The electronic control panel and buttons should be prevented from direct or indirect contact with solvents such as thinner and oil water to prevent damage.

④ The purpose of frame paint is to keep the machine from rusting and to prevent damage caused by direct or indirect contact with solvents such as thinner and oil-opening water.

⑤ The sewage and dirt in the oil mist combiner should be discharged in time to prevent it from entering the pneumatic components and affecting the normal operation. The cup body should be cleaned regularly and lubricating oil should be added to the oil cup of the oil mist combiner .

⑥ When adjusting the flow limiting valve, you must first loosen the locking nut before adjusting it by hand. The handle screw on the machine is used for positioning. After it is firmly positioned, there is no need to tighten it too much.

⑦ After work, turn off the power supply / gas source, clean the screen, and keep it properly to prevent dust / pressure / puncture from hard objects.